DTF Printing Demystified: Everything You Need to Know About Direct-to-Film

DTF Printing Demystified: Everything You Need to Know About Direct-to-Film

Blog Article

Ultimate Overview to DTF Printing Methods for Magnificent Fabric Designs

Beginning on the trip of grasping DTF printing strategies can open up a world of possibilities for creating aesthetically exciting fabric designs. As the textile sector remains to develop, staying ahead of the contour with innovative printing methods is essential. In this guide, we will check out the elaborate details of DTF printing, from grasping the fundamental fundamentals to unraveling advanced color strategies that can elevate your styles to new elevations. Stay tuned as we look into the subtleties of selecting the best materials, perfecting the printing procedure, and getting over common difficulties to achieve magnificent results.

Comprehending DTF Printing Essentials

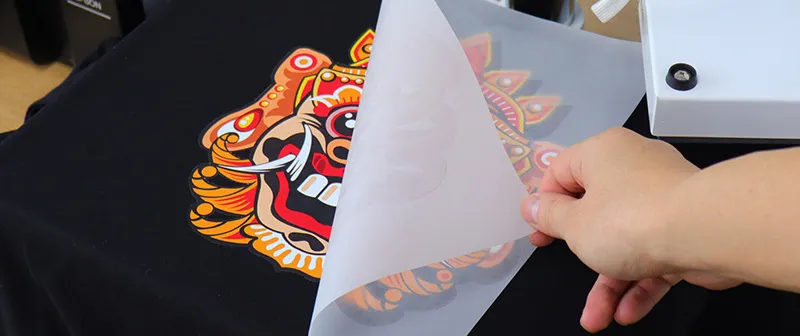

DTF printing, a process that entails transferring designs from a special film to textiles making use of warm and stress, develops the foundation of fabric printing techniques. The very first action in DTF printing includes producing or selecting a layout that will certainly be published onto the textile.

The final result is a sensational, resilient fabric design that is cleanable, adaptable, and resistant to fading. On the whole, understanding the fundamentals of DTF printing is crucial for understanding this modern textile printing technique.

Selecting the Right Textile Materials

Having developed the fundamental principles of DTF printing strategies for textile designs, the next critical factor to consider hinges on selecting the ideal fabric products to match this innovative procedure successfully. The success of a DTF print greatly depends upon the compatibility in between the picked material and the printing strategy. When choosing fabric products for DTF printing, it is necessary to take into consideration the textile's make-up, weave, and texture. Fabrics that work well with DTF printing consist of polyester blends, spandex, nylon, and various other artificial materials. These materials usually have a smooth surface that permits vivid and thorough prints. In addition, the stretchability of these products can accommodate the heat transfer procedure associated with DTF printing without misshaping the design. It is suggested to prevent all-natural fibers such as cotton or silk, as they may not produce the exact same degree of print quality and durability. By choosing the appropriate fabric materials, designers can maximize the possibility of DTF printing to create stunning and long-lasting textile designs.

Grasping the Printing Refine

To stand out in DTF printing strategies for textile layouts, understanding the printing process is essential for achieving constant and high-grade results. The temperature, pressure, and duration of warm application must be very carefully controlled to ensure proper attachment of the style to the textile. By refining each of these steps in the printing procedure, designers can continually create durable and stunning fabric styles with DTF printing methods.

Enhancing Designs With Shade Techniques

Moreover, trying out color gradients can bring a feeling of activity and fluidness to the design. By mixing colors effortlessly, a gradient effect can be accomplished, including a dynamic and modern touch to the textile design. Additionally, using shade blocking methods can produce Clicking Here striking and vibrant visuals by comparing various strong shades in unique sections of the layout.

Additionally, integrating metallic or neon shades can provide a attractive and unique component to the fabric layout, making it attract attention and exude a feeling of vibrancy. When tactically applied, these shade techniques can elevate the total aesthetic appeal of fabric designs, making them much more remarkable and fascinating.

Troubleshooting Common DTF Printing Issues

After exploring numerous color techniques to boost textile layouts, it is necessary to deal with common DTF printing concerns that might arise throughout the manufacturing process. One usual problem is inadequate bond, which can arise from incorrect healing temperature levels or times. To resolve this issue, ensure that the curing settings are precise which the adhesive utilized is suitable for the certain material being published on. Another regular obstacle is color disparities, where colors may show up differently than expected. This can be created by incorrect shade accounts or setups in the printing software. To tackle this, verify the color settings and accounts to guarantee they match the intended layout. Additionally, issues with picture clarity and intensity can occur as a result of low-resolution images or incorrect printing techniques. To address this, always utilize high-quality pictures and readjust the printing setups for optimum clarity. By knowing these common issues and carrying out the necessary troubleshooting steps, you can enhance the overall high quality of your DTF published fabric layouts.

Conclusion

To conclude, grasping DTF printing techniques is essential for creating magnificent textile styles. By comprehending the basics of DTF printing, choosing the appropriate products, and boosting layouts with shade techniques, one can achieve remarkable outcomes. It is essential to repair usual concerns that might arise during the printing process to ensure an effective result. With practice and interest to detail, one can produce gorgeous and unique textile designs using DTF printing methods.

DTF printing, a procedure that involves moving layouts from a special film to textiles utilizing heat and stress, forms the structure of fabric read this printing techniques.Having actually developed the fundamental concepts of DTF printing methods for fabric designs, the next essential consideration exists in selecting the suitable fabric products to complement this cutting-edge process efficiently. By investigate this site picking the right textile materials, developers can make best use of the potential of DTF printing to produce lasting and magnificent fabric designs.

To excel in DTF printing methods for fabric styles, grasping the printing procedure is essential for achieving high-quality and consistent outcomes. DTF Printing. By sharpening each of these actions in the printing procedure, developers can continually generate stunning and resilient textile styles with DTF printing techniques

Report this page